Giben Optisave 5.3

14-09-2010, 10:09. Author: vipsoft

The new Windows version of GIBEN OPTISAVE cutting patterns optimising program is based on 32 bit technology and thanks to Windows, represents a simple optimisation tool for the user.

The 32 bit technology definitely helps in reducing working times, thus offering further important advantages:

Mouse and windows user interface control

Cutting pattern overall view with zoom function

No limit in managing quantities of parts with same and different sizes

No limit in board sizes

Production control of more machines in network

Link from and to the optimising program and control of the machine

Simple import & export functions

Simple optimisation control by different parameters lists with windows user interface technology

INFO

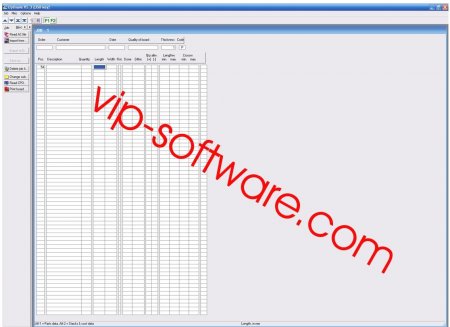

The OPTISAVE control menu is on the left hand side of the screen.

The user enters the operating windows and moves to another just by a mouse click.

The windows user interface technology increases its friendly use, thus allowing the handling of different processes.

The optimisation can be controlled by using different parameters.

The parameters are available to the user divided into groups (trim cuts handling, cycle times, limits)

Simplicity makes OPTISAVE easy to use.

The integrated control of rests/stock and the possibility to optimise optional parts assure brief material storing times, reduction of rests storage with consequent decreasing of stocking value.

All cutting patterns per job are clearly available on the screen.

By a mouse click the user can look through a given cutting pattern or modify it manually.

Zoom function allows further views.

By using Page Up and Page Down keys the user can browse to following cutting pattern and get back to the previous one or can enter the overall view page.

Different analyses can be worked out each job in the form of cutting lists, pile or protection boards list.

The following information is available for each job:

Cut parts and optionals.

Quantity of raw boards used.

Waste, cutting times.

Number of cutting patterns, cycles and unloading stations.

Required cutting time.

IMPORT & EXPORT FUNCTIONS

Our OPTISAVE standard user interface offers the possibility of connection with managing systems (part lists acquisition, cutting data and times feed back) as well as of serial and network link for the control of the panel saw.