Article info

19-04-2010, 11:52

- Views:

- Author: vipsoft

- Date: 19-04-2010, 11:52

EZCAM EDM 15

Category: CAD/CAM CNC

General

The wide array of intuitive CAD functions are the foundation of what makes

EZ-EDM the easiest to use CAM system available today. Automatic filleting, advanced trimming commands and mathematical function plotting are just a few examples of EZ-EDM state-of-the-art CAD features. Create geometry in any plane using the Multiple User Coordinate Systems. Import IGES, DXF and VDAFS geometry files. IGES loading is optimized for importing all major CAD system files. Dynamic rubberbanding lets you preview the results of a command before completing it; and if you still make a mistake, you can undo/redo up to 25 consecutive commands.

Solid and surface models can now be imported via IGES and STL. Machining curves can then easily be extracted as cross sections from all visible surfaces. Extensive 3D surface creation and editing functions are also provided. Dynamic Rotation, Panning and Zooming of all geometry and toolpaths lets you more quickly and easily change views and inspect your parts. Built-in BASIC macro language editor provides extensive macro writing capabilities, allowing end users endless customization options within the product. Postprocessor definition language supports BASIC scripting.

Machining

Get the most out of your wire EDM using modern machining technologies, based on several years of shop floor experience. Define multiple cuts for roughing and finishing using user definable technology database. Let the software cut back and forth or automatically create subprograms for every contour. Define single or multiple stoppoints. Easy creation of cylindrical and conical shapes for output as angular or four axis XY-UV NC code.

Punch and Die Design wizard lets you select pre-defined machining strategies which greatly simplifies programming. It includes a new Taper & Land option that lets you quickly enter in angles and land height for all possible combinations. New auto-sequencing options give you full control over the order of rough, finish and cut-off operations for multiple or single profiles. 3D Solid Model Preview function lets you watch your part being cut from a solid block of material. A toggle lets you switch between the cavity, cut-out, or wire path pieces, and you can dynamically rotate, pan and zoom the model for full inspection.

Post Processing

EZ-EDM comes with a library of post processors for the most commonly used EDM machines including: FANUC, SODICK, JAPAX, AGIE, CHARMILLES, MITSUBISHI, and MAKINO. And you can easily build your own post-processor files for virtually any CNC control with the included EBuild utility. A new EZ-DNC G-code text editor with DNC RS232 communications is also included.

Go Back

Comments: 0

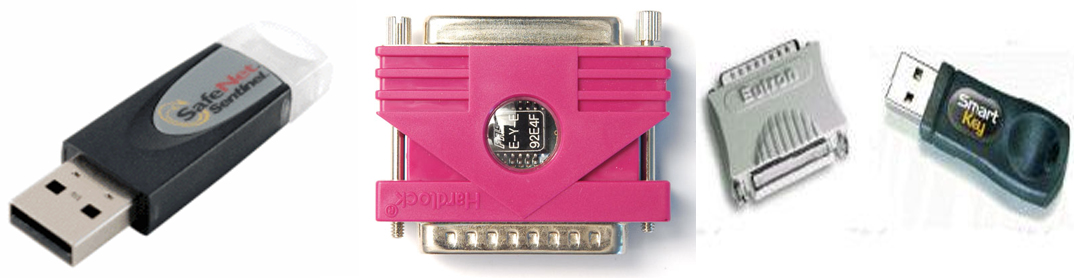

Dear visitor, Our Softwares not FREE and all work with usb dongle if you interesting buy

Contact ME

Contact ME