Article info

17-06-2013, 15:18

- Views: 4470

- Author: vipsoft

- Date: 17-06-2013, 15:18

GPS.Opt 7.55

Category: Other Software

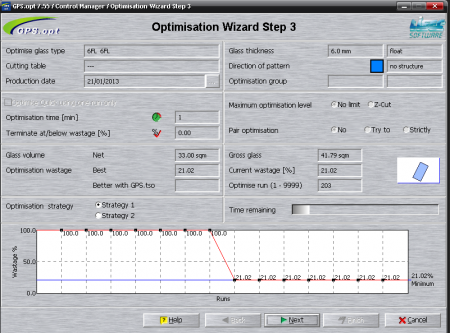

Focusing on wastage results alone reserves GPS.opt the top position in the industry’s software solutions. GPS.opt also allows a seamless integration into the production control software and the associated benefits of using a range of perfect planning tools to layout the cutting schedule. This secures a competitive edge for your company.

In combination with TSO – the first true shape optimizer, GPS.opt increases the potential to save material and therefore money.

With GPS.opt you can decide to use A-racks or harp cars to stack the glass after cutting. The stacking method makes no difference to the system. The program optimizes the space required on the racks taking into account the production sequence and packing requirements.

The stock plate editor allows the operator to modify the optimization and add new sizes manually or insert remakes to avoid wasteful remnant sheets. Normal optimizers surround shapes with a rectangle to allow breakout, but this increases the wastage enormously. TSO however integrates the shapes together, which reduces the waste signifi cantly. The degree of nesting can be selected using parameters in GPS.opt, but the system automatically generates help cuts to aid the breakout of complex shapes.

"DXF, CAD, CNC”, these technical words are part of the GPS.opt vocabulary. Using these standard interfaces GPS.opt can receive geometric code and convert it into control code to directly run cutting tables, glass loading systems.

- See more at: http://www.lisec.com/en/Automation/Production-Management/GPS.opt#description

Go Back

Comments: 0

Dear visitor, Our Softwares not FREE and all work with usb dongle if you interesting buy

Contact ME

Contact ME