Design assyst

Eliminate sample production with this comprehensive and user friendly graphics software package, developed for the clothing industry. Produce storyboards and colour ways, using R.G.B and /or Pantone© colours.

Create and modify fabric designs and visualise the results using the latest draping techniques. Include fabric effects and fills to show accurate and informative specification drawings and illustrations.

Available as a plug-in to Photoshop™

The knitting and weaving modules enable knits and plaids to be created and realistically displayed -

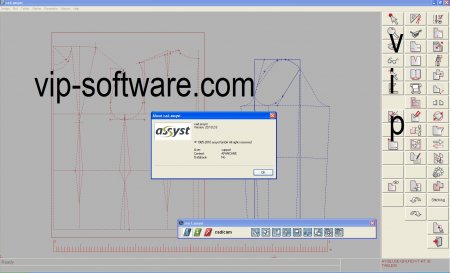

trouser patternCad.assyst

Cad.assyst is an easy to use programme enabling the user to create or modify patterns quickly and accurately.

Patterns can be entered onto the system by digitisation of existing styles or receive them by importation from other software or draft directly on the screen.

Construction and measurements can be checked accurately and modified where required.

Seams added change automatically with pattern amendments and added to split pieces.

The grading functions can be used to create a size range of your choice.

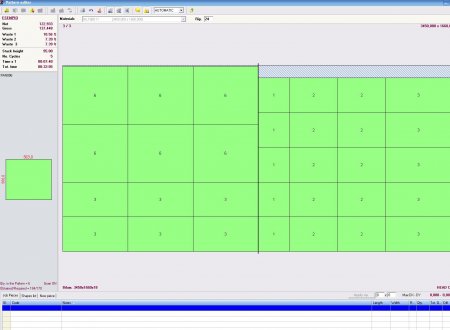

Create ratings or markers to get maximum utilisation of your material.

Nesting can be directly on screen, by automatic placement or automarker.com

Smart pattern automates regularly performed tasks to standardize and de-skill operations such as facing and lining creation etc.

download document in PDF format (3230 kb)

vidyaVidya

Takes your Cad patterns, assembles them and tries them on a virtual body.

See how your garment fits in real time, make pattern adjustments and see the effect immediately, see where the material is under tension as the body moves, sits down, turns etc.

As well as dramatically reducing pattern development time, vidya can also be used to create and view made to measure garments.

download document in PDF format (3810 kb)

fit sleeve to armhole with easeMtm.assyst

The made to measure programme enables a reduced timescale from customer order to delivery via an easy, user friendly interface, entering client measurements to produce accurate patterns tailored to the individual’s requirements.

The skills of the tailor/ pattern maker are harnessed in the assyst software to enable a consistent standard of amended patterns.

Customer measurements for made to measure production are easily achieved using data from body scanners.

download document in PDF format (3230 kb)

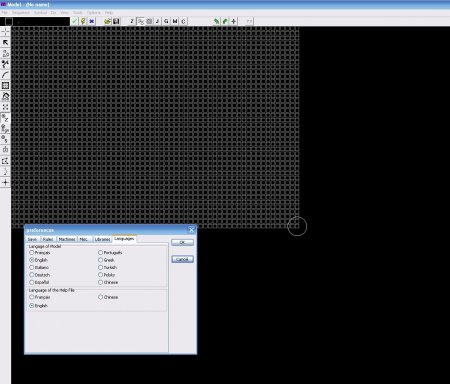

Dataconv.assyst. conv.cad and Dataviewer

Globalisation of production requires that patterns are sent to other locations.

To save time and money sending hard copy patterns or markers

Dataconv.assyst enables effective communication data with your manufacturers either directly or via the internet using automarker.com

DXF (Autocad™ etc) drawings can be converted using data viewer

DXF (Autocad™ etc) drawings and data in Gerber™, Lectra™, Investronica™, Microdynamics™ can be converted using data viewer

laundryPDM4Cad

Organise and centralise the product development data to enable all departments to update and view progress in real time.

Eliminate mundane paperwork and clearly illustrate the product lifecycle from concept to the start of manufacture using comprehensive specifications, bill of materials, measurement charts and reports etc.