Article info

15-02-2012, 12:17

- Views: 3442

- Author: vipsoft

- Date: 15-02-2012, 12:17

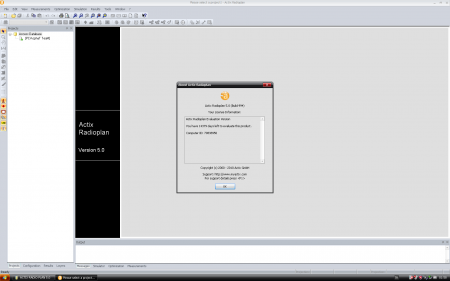

Actix RadioPlan 5.0

Category: Telecom Software

Radioplan - RF Optimisation

Desktop Automated Cell Planning Software

Radioplan is an offline, desktop automated cell planning software. Radioplan uses network OSS, drive survey and planning data for optimizing the configuration of new sites and site overlays.

During the design phase of a new technology overlay such as LTE, operators must balance complex design decisions such as achieving coverage & capacity objectives with business drivers such as minimizing capital investment while maximizing revenue generation. As each design has hundreds or even thousands of variable elements, selection of an optimal design for a given set of business and technical objectives is simply not possible using manual trial and error.

Radioplan automates the process of identifying an optimal design configuration, using intelligent algorithms to efficiently explore an enormous, mind-boggling solution space. Radioplan has delivered substantial CAPEX reductions while improving performance and capacity in hundreds of real-world deployments.

Radioplan optimizes cell plans to minimize CAPEX and maximize performance.

Radioplan desktop automated cell planning software supports 2G, 3G and 4G/LTE technologies. Radioplan may be deployed on a standalone basis or as a complement to ActixOne, which provides superior automation of day-to-day planning activities, but does not include the full range of adhoc and expert analysis capabilities of Radioplan.

Article info

15-02-2012, 12:14

- Views:

- Author: vipsoft

- Date: 15-02-2012, 12:14

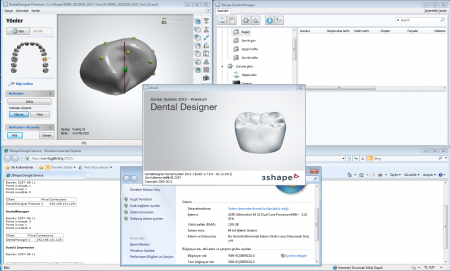

3Shape Dental System 2.7 2012

Category: CAD/CAM CNC

CAD Design

3Shape CAD Design Software

Used in thousands of labs worldwide. Interested?

Contact a reseller today...

Contact Reseller

...or download our Dental System Free brochure

CAD/CAM Design

3Shape Dental SystemTM is known throughout the dental industry as the most powerful CAD/CAM design system in the world.

Empowering technicians with automation and productivity

3Shape's CAD Design software supports familiar workflows, provides the market's most comprehensive dental indication support and greatly enhances productivity through extensive automation.

Continuous support - we are always behind you

3Shape's Dental SystemTM is backed by professional technical customer support and dedicated 3Shape Academy training programs.

See Software Video

bla

Newest features in Dental System™ 2012

include: Model Builder™, 3Shape Communicate™, Digital Temporaries & Virtual Diagnostic Wax-Ups, 2D Image Overlays, Optimized Dynamic Virtual Articulation and Smile Composer™.

With a 3Shape license you stay ahead

Your annual Dental SystemTM license entitles you to free system patches and software upgrades, ensuring that you continuously maintain your competitive edge by working with the best technologies available.

Article info

15-02-2012, 12:11

- Views:

- Author: vipsoft

- Date: 15-02-2012, 12:11

Vectron Commander 6

Category: Other Software

ntelligently networked

PLU range and -prices require a continuous update. Turnover as well as order- and working time data registered at the point of sale are to be managed. The communication software Vectron Commander provides extensive possibilities with only minimum effort. Though the Vectron-POS systems already offer numerous programming- and report options, the application of Vectron Commander has decisive advantages for instance in terms of program data maintenance and reporting. Modifications of PLU-related data can be transferred to one individual cash register or to any group of ECRs. Vectron Commander connects the head office of a company to all branch systems - worldwide if required. This guarantees that all POS systems work with the same data whilst requiring only a minimum of administration.

The communication between POS system and PC is established either via direct cable connection, PC-network or via telephone connection. The Vectron Commander supports analogue-, ISDN- and mobile radio networks.

Programming and polling of data

Multi-user capability and a sophisticated safety system allow the evaluation of turnover figures at one workstation whilst at the same time at another work station new prices are entered. Parallel, additional computers exchange data with the cash registers; even in extensive branch networks, all POS systems can be read out and updated practically without delay. The Vectron Commander is fully scalable and can be applied group-wide. In small and medium-sized companies all functions can be bundled on one single PC. A password during program start guarantees that each user can only see and modify those data for which he is authorized.

Flexible ECR reports

The polled report data can be consolidated for any cash register, group of ECRs, periods and PLUs and can be compiled to clearly arranged reports. In addition to the wide range of standard reports, the report generator enables you to draw up any individual data analysis that you require - be it sales- or staff-related. Alternatively you export data in Microsoft Excel format and import them directly into reports, diagrams and presentations.

The open and well-documented data interface is the key for the integration of the Vectron Commander into Back-Office-solutions. Thus, you transfer for instance item-related data from your stock control program to the POS systems or take over time and attendance information into working hour registration. Many providers of trade-specific Back-Office-solutions already realised a connection to this interface. For more information please contact your local sales representative.

Vectron Commander 7

Version 7 of the versatile communication software Vectron Commander offers a new graphical user interface as well as numerous convincing new functions. In addition to the useful features of the previous version like simplified data administration of all networked POS systems and automated data transfer and -evaluation, Vectron Commander 7 can now carry out the complete programming and configuration of the connected Vectron POS systems.

Easy programming

Newly introduced "Assistants" simplify programming. These tools serve for instance for creating, changing or deleting icons and buttons. The programming of the GUI, the keyboard assignment of the POS systems and the creation of table plans is also carried out easily and rapidly via supplied assistants. The assistant for text forms for example serves for creating order forms.

Intuitive graphical user interface

The completely new layout of the graphical user interface and the improved user guidance make the handling of the communication software even clearer, easier and more intuitive. This makes the Vectron Commander 7 more than ever the central control element for all Vectron POS systems.

Article info

15-02-2012, 11:43

- Views:

- Author: vipsoft

- Date: 15-02-2012, 11:43

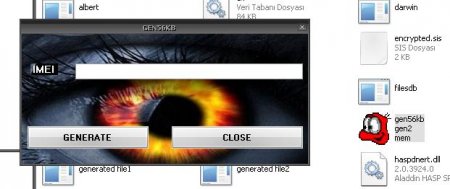

56Kb Spy Phone Generator

Category: Other Software

or all firmware version OS 9.1 9.2 9.3 9.4

More stable software solution, support remote room listening for all firmware version include N97, 5800, 5530, Samsung i450, Nokia E66 (Firmware date 2009/06 or higher), E71 (Firmware date 2009/06 or higher), N86, E72 and all firmware version.

GPS location report support for device with GPS with Lat, Log, Alt location

Support call number watch list, only watch list number will send alert to PDN

Support SMS text message filter.

No log for all SMS and call

No application show in setup manager

Article info

15-02-2012, 11:40

- Views:

- Author: vipsoft

- Date: 15-02-2012, 11:40

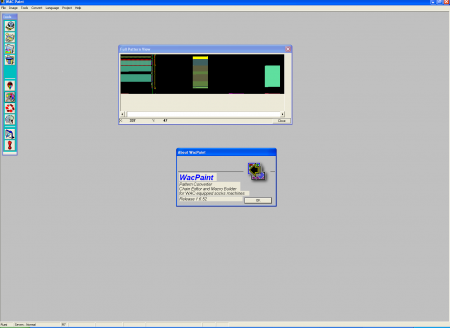

Wacpaint 1.6.52

Category: ---

WAC design system WAC PAINT

. WAC PAINT is a graphical planning environment for textile

machines equipped with WAC electronics.

. WAC PAINT contains a graphical editor for files in WAC

format and a program of automatic processing of designs BMP.

. WAC PAINT is a 32-bit application compatible with

Windows 2000 and XP.

. Set of samples for printing shown through the

REAL KNITTING VIEW

Article info

15-02-2012, 11:39

- Views:

- Author: vipsoft

- Date: 15-02-2012, 11:39

WinSteel 6.50

Category: CAD/CAM CNC

Steel Projects is a leading European Software Development Company. Our market leading Windows

based modular CAD CAM Production software (WinSTEEL) has provided tremendous time and cost

savings to Structural Steel Fabricators for over 20 years.

· Scribing – automatic import and scribing of associated parts and their

marks, less human errors enabling fast accurate throughput and assembly

· Bar Coding – instant tracking and database update of parts from arrival,

through manufacture to dispatch and assembly

Our fully integrated modular software provides the Structural Steel Fabricator with the solution they

have been searching for, a scalable system to track and monitor both labour and material from

estimation to delivery.

From Estimating, Contract Management, Suppliers, Material Enquiries, Purchasing, Orders, Invoices,

Material Delivery, Stock Control, CAD Import, Bar and Plate nesting, Machine Timings, Bar Coding,

Employee Time Cards, and Part Audit Trail to CAM file routing to machines

· Estimating – quickly create accurate concise estimates using latest supplier

price information from manual input, from imported excel sheets or

WinSTEEL import

· Purchasing – automatic creation of contracts and prelim material lists,

generate pricing enquiries, raise orders receive deliveries

· Stock – stock control, automatic material addition from orders, material off

cuts automatically added, reports materials received and allocated,

outstanding orders

· Time – instant automatic allocation of employee time against actual contract

/ part / activity, salary preparation, true contract costing and timings

· Cost – up to date, accurate comparison between budget and actual cost,

easy comparison and reporting

· WinSTEEL - importation of CAD files, contract phase and part management,

profiles database, machine and tooling cycles

· WinSER – optimized machine routing, machine cycle times for parts and

bars, machine load optimization, contract / load status at a glance, automatic

feedback of machine times, planning control

· Nesting – Bar and Plate nesting, easy to use, fast and accurate, minimizes

waste, improves productivity

· Post processors – maximize operator efficiency with single GUI, easy to

use drag and drop functionality, available for all types of machines

Steels Projects is the only software system that provides on-going feedback on workshop efficiency

and machine utilization direct to the Production or Workshop Manager’s PC.

The real-time information provided can then be used to create reports on the efficiency of individual

machines or the overall workshop. This data is invaluable to any manager requiring confirmation of or

revision to current time scheduling, stock control, purchasing, nesting, cost analysis and capitalization

of new machinery.

Our software package really is one of the easiest ever systems to implement and the modular nature

of the software enables clients to choose to introduce the module, or modules, that best suit their

business or working practices, thereby gaining the maximum financial benefit.

From large to small structural steel fabricators we help maximize their production efficiency, reduce

their costs and increase their profitability.

Previous

Next